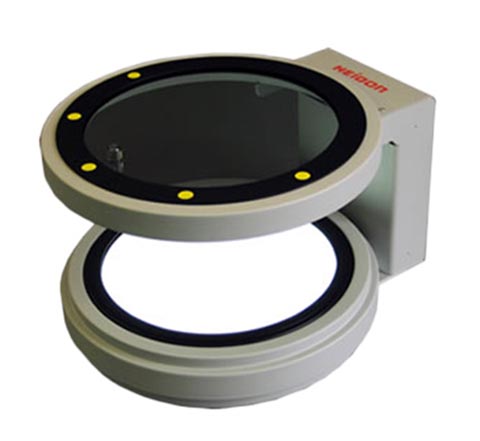

This is a strain tester using light deflection that is easy to use with high illumination and high field of view. It uses inverter round fluorescent lamps, which are less flickering and easier on the eyes, so it can be used for long hours of inspection. The effective field of view is as wide as 280mm in diameter, allowing inspection of large specimens or observation of several types of specimens at once for easy comparison and examination. The analyzer (upper polarizer: analyzer) can be rotated to allow observation in dark field or bright field conditions.

Two measurement methods

The TYPE:25W uses the orthogonal nichol method, which is good at observing the flow state of plastic molded products, and the TYPE:25WS uses the sensitive color method, which enables observation of minute distortions in glass. You can choose the observation method best suited for your observation.

Main purpose of use

The main purposes of use are to determine flaws in glass products, to inspect the state of stress concentration near the gate of plastic molded products, to inspect heat seal joints, to observe the state of gel dispersion in film, to inspect unevenness in strain caused by film winding, to test stress distribution in transparent models of mechanical parts, and to check the state of distortion of cutting surfaces caused by wear of cutting blades. The following are some examples.

warpage-checker

TYPE:25W/25WS

This is a strain tester using light deflection that is easy to use with high illumination and high field of view. It uses inverter round fluorescent lamps, which are less flickering and easier on the eyes, so it can be used for long hours of inspection. The effective field of view is as wide as 280mm in diameter, allowing inspection of large specimens or observation of several types of specimens at once for easy comparison and examination. The analyzer (upper polarizer: analyzer) can be rotated to allow observation in dark field or bright field conditions.

Two measurement methods

The TYPE:25W uses the orthogonal nichol method, which is good at observing the flow state of plastic molded products, and the TYPE:25WS uses the sensitive color method, which enables observation of minute distortions in glass. You can choose the observation method best suited for your observation.

Main purpose of use

The main purposes of use are to determine flaws in glass products, to inspect the state of stress concentration near the gate of plastic molded products, to inspect heat seal joints, to observe the state of gel dispersion in film, to inspect unevenness in strain caused by film winding, to test stress distribution in transparent models of mechanical parts, and to check the state of distortion of cutting surfaces caused by wear of cutting blades. The following are some examples.